Artificial intelligence medical equipment for stem cell industrialization

2022-01-05

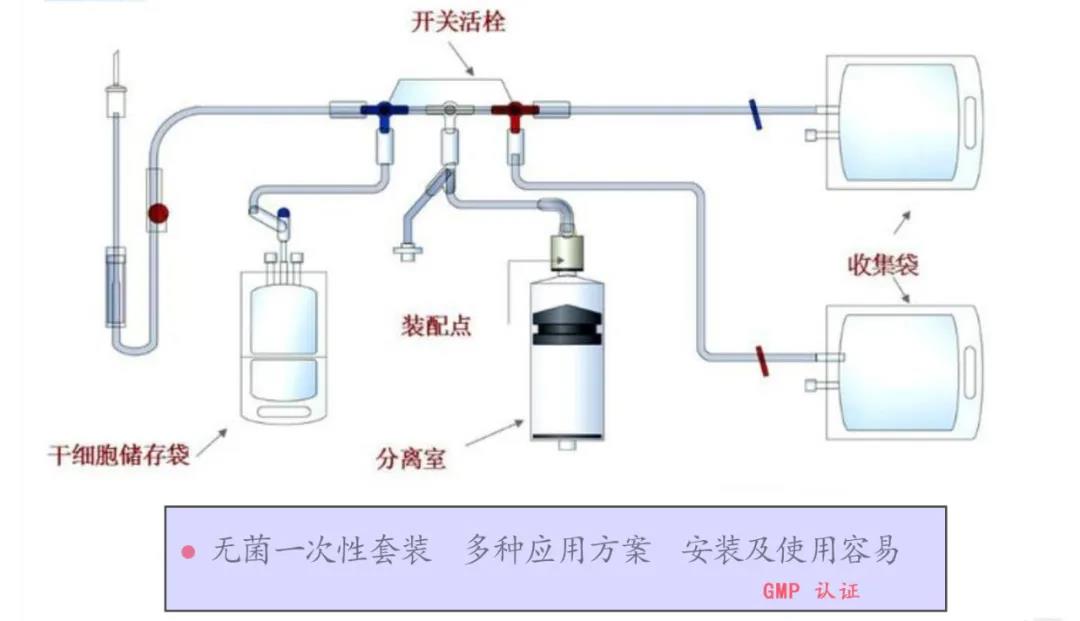

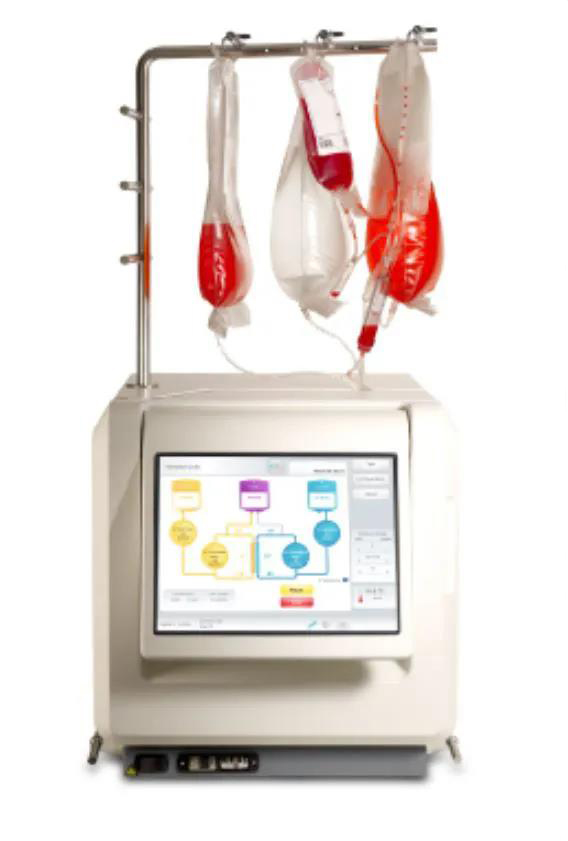

Sepax cell processing system is a new type of cell centrifugation equipment, suitable for the separation of bone marrow, umbilical cord blood, peripheral blood. Sepax separation processing volume range is relatively large, between 30-880ml. The whole device is airtight and sterile, and the stem cells are processed quickly and automatically. Stem cells are collected in standardized blood bags for further processing, such as cell sorting, concentration, washing, cryopreservation, or stem cell transplantation into patients.

Small, lightweight and versatile, the SEPAX system is an ideal platform for blood component processing, with high recovery rates and guaranteed high cell viability after processing.

Boya Stem Cell launched Boya AXP automatic separation equipment in 2007.

XP® II is the second generation of Boyaa’s fully automatic stem cell separation system. With the matching cell separation consumables device, AXP® II can automatically, quickly and continuously remove the umbilical cord blood unit while ensuring the environment is completely closed and sterile. collection of stem and progenitor cells. In November 2018, the AXP® II System received U.S. Food and Drug Administration (FDA) 510(k) marketing clearance for use in clinical-grade blood banks. Approved by Health Canada in June 2019. The AXP® II system has reliable volume reduction processing capability, capable of reducing the volume of umbilical cord blood to a custom volume within 30 minutes, standardizing the processing process, and processing 6 samples simultaneously. The AXP® II system can achieve over 90% mononuclear cell (MNC) recovery and over 95% CD34+ cell recovery. Operation of the AXP® II system is simple: the cord blood is transferred from a standard sampling bag to the device and centrifuged. The blood is then separated into red, white and plasma segments. The AXP® II system automatically separates these components into separate sections. Collect into corresponding separate collection bags for easy access.

The Quantum system of foreign BCT company is also relatively powerful. The biggest advantage is that it only takes 20 minutes to collect cells.

Of course, there are other brands that can directly separate the cell buffy coat layer, that is, the mononuclear cell layer, from the whole blood, such as the Italian Silfradent CGF centrifuge, etc., but the one-time processing capacity of these devices cannot meet the above requirements. One hundred milliliters of cord blood.

2. Stem cell storage device (system)

A common cell storage device is a liquid nitrogen tank. There is a very simple metal tank, and there are also liquid nitrogen tanks with their own intelligent monitoring systems, such as Jinximeng gas-phase liquid nitrogen tanks. Gas-phase liquid nitrogen tanks have attracted much attention due to some advantages such as reducing microbial contamination and cryotube explosion.

The Jinximeng gas-phase liquid nitrogen tank can store cryopreservation tubes and blood bags at the same time. It is equipped with automatic filling control and alarm system. Optional battery can improve the safety factor.

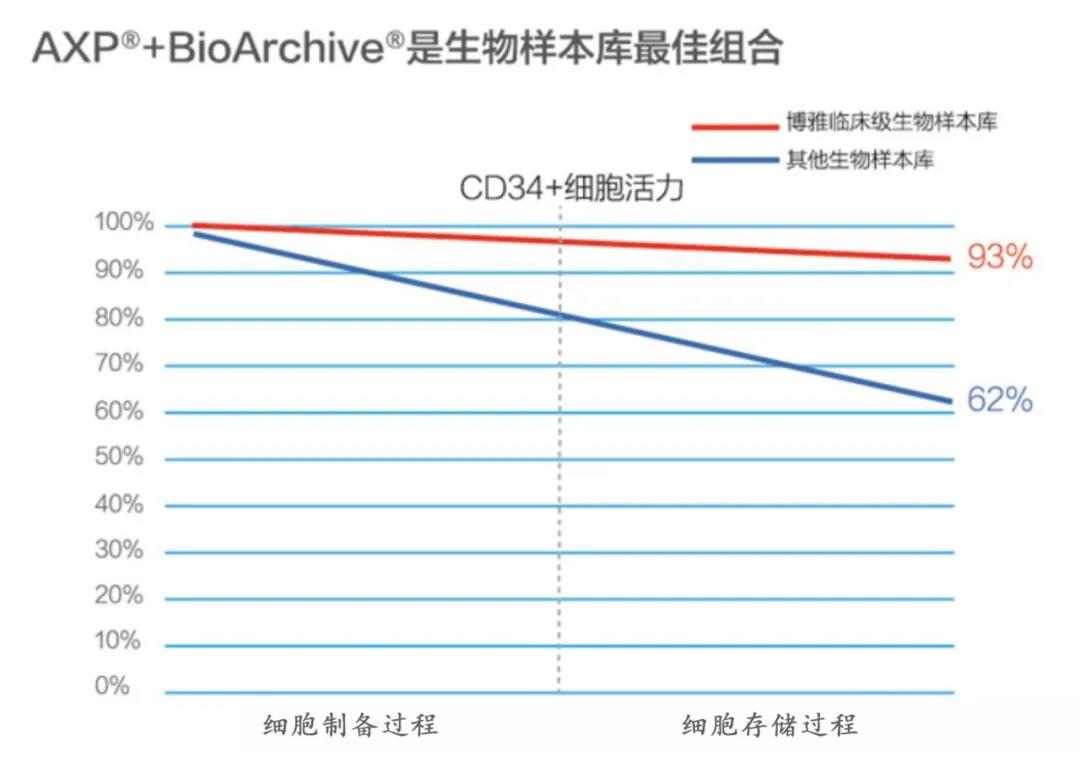

The AXP automatic preparation system developed by Boya Group's subsidiary is matched with the BioArchive automatic storage system, which can better realize intelligent automatic production.

After cell preparation and storage, the viability of CD34+ cells was as high as 93%, while the viability of CD34+ cells in other biobanks was only 62%.

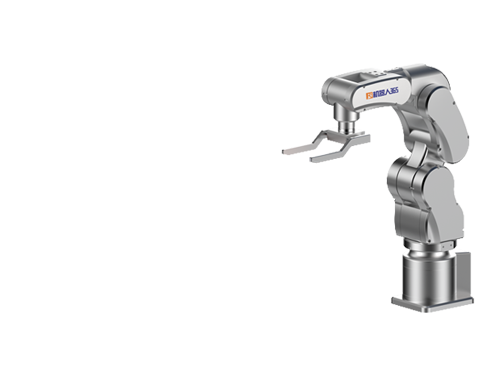

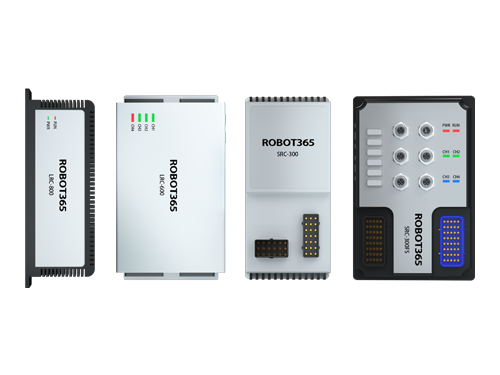

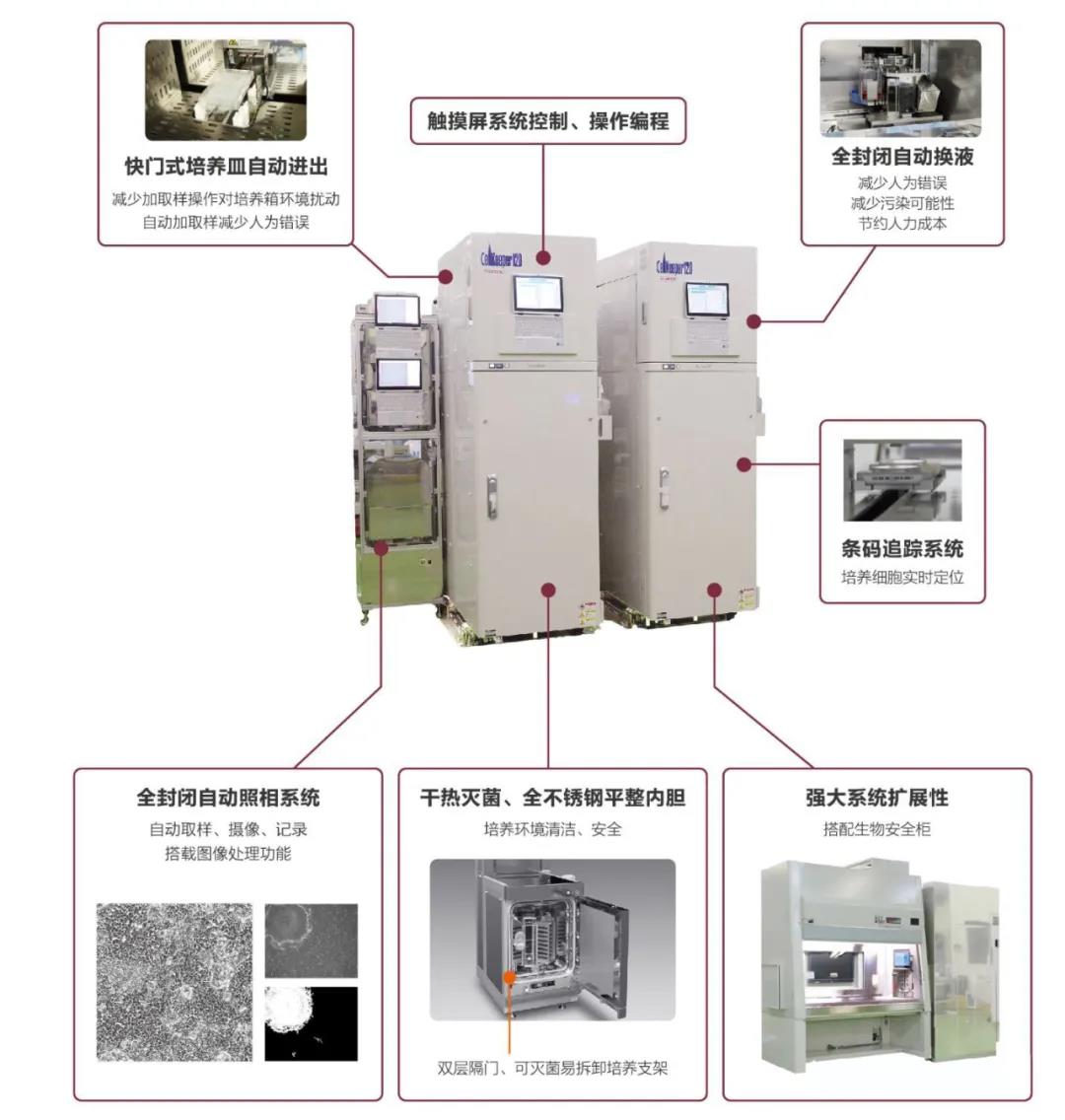

ROBOT365-LOT Stem Cell Culture System

Under the development strategy of "AI+ROBOT", Robot 365 started to incubate the "Stem Cell Cultivation Robot" project by using its own technological advantages. The project combines medical treatment, robotics, artificial intelligence, and through independent research and development, to produce robotic products for clinical applications such as stem cell extraction, culture medium injection, trypsin cleaning, biopsy, and cryopreservation. With the gradual presentation of the technical achievements of the "Stem Cell Cultivation Robot" project, its mainstream products have been put into clinical trials and successfully obtained angel investment.

ROBOT365-LOT Stem Cell Culture System Developed by Robot365

4. Stem Cell Differentiation Equipment

To use embryonic stem cells and/or iPS cells to treat diseases, it is necessary to induce and culture embryonic stem cells and iPS cells, completely differentiate into mature functional tissue cells, and then transplant these differentiated and mature functional cells into the body to replace sick or dead cells. tissue cells to play a therapeutic role. This induced differentiation must be complete. If it is not complete, these cell populations still contain surviving embryonic stem cells and/or iPS cells, then these stem cells with strong differentiation potential are likely to undergo various uncontrolled differentiations, that is, become cancer cell.

In terms of intelligent equipment for stem cell differentiation, both Japan and my country are at the forefront.

RORZE-ReMed is committed to the development and application of automated cell culture equipment.

The official propaganda has proved that the survival rate of somatic cells cultured by automatic equipment is almost the same as that of experienced artificial culture, and the survival rate of iPS, ES (embryonic stem cells), and MSC (mesenchymal stem cells) cells is 10% better than that of artificial culture.

Clinical needs determine technical requirements, and technical requirements determine the overall plan. This is a process of continuous iteration and long-term investment. In the future, all parties to the cooperation will integrate resources in the field of "production + academia + research + application + medicine + engineering", give full play to the advantages of all parties, form a cohesive force for collaborative innovation, achieve efficient technology transformation, and open up the transition from "laboratory" to "surgery". "Taiwan" bridge, and promote the progress of medical science and technology.

With the development of the overall industry of intelligent manufacturing, it is believed that the entire industry chain of stem cells can realize intelligent automation, so as to realize large-scale industrialization of stem cells, and the arrival of stem cell drugs will make a huge contribution to a healthy China.

Note: Part of the content of this article is mainly from the public materials on the official website of the device or biological company . Mainly used for information sharing.