Behind the nucleic acid detection, how to innovate the automation of biological laboratories?

2022-03-22

How many nucleic acid tests have you done this year?

When the new coronavirus broke into human life, nucleic acid detection became a rigid need for epidemic prevention, and the "laboratory automation" track heated up instantly, and robots in the field of life science automation became more valuable.

The laboratory automation assembly line started in the 1950s and entered China in 2009. According to the degree of automation, it is divided into two categories: TTA and TLA . The former is a modular combined analysis system with functions as the core, and the latter is an unmanned operation. fully automatic laboratory assembly line. The advantages of saving report turnaround time, improving test throughput, liberating manpower, reducing manual errors , and high environmental cleanliness determine that automated assembly lines will be an important link in the future of life science laboratories.

Robot 365 Company , located in Songshan Lake High-tech Park , based on the cutting-edge field of life science automation research - cell industry automation, has developed the world's first humanoid nucleic acid detection robot equipment, which has significantly improved the efficiency of subsequent epidemic prevention and control. The laboratory automation industry has thus been pushed to the center of the market. Data shows that in 2021 , the global laboratory automation ( TTA and TLA ) market size will reach 8.53 billion yuan, and it is expected to reach 1.448 billion yuan in 2026 , with a compound annual growth rate ( CAGR ) of 6.5 % . In the future, this track will continue to explode. In addition to " nucleic acid detection robots " , Robot 365 brings more " robots " into the field of life sciences to serve human health.

Entrepreneurial Action for "Change Labs"

In June 2020 , the Robot 365 technical team received the first requirement for the development of life science laboratory automation, a cultivation robot for cell laboratory automation. At that time, the customer had already purchased foreign product orders, and the final delivery could not be completed due to the epidemic. The customer had to turn to China for cooperation. Introduced by industry friends and in-depth technical evaluation, the Robot 365 team, which has been engaged in the robot industry for more than 10 years, took this customized order. After the cross-border integration and close cooperation of artificial intelligence and life science teams, the product delivery will be completed in October 2021 and will be highly recognized by customers and expert leaders. The client side not only paid the order in full at the first time, but also made additional investment in the project, becoming one of the investors in the Angel Wheel of Robot 365 Company. The scene at that time made the Robot 365 team firm in the direction of life science automation .

Core technical team with industrial robot background

In June 2016 , the Robot 365 team with R&D, engineering background and project management experience embarked on the road of entrepreneurship and participated in the R&D and mass production of many precision instrument products. The early Robot 365 project was defined as the field of intelligent manufacturing, solving labor difficulties and production automation pain points for customers in the industrial automation industry.

Determining the direction of laboratory automation is based on industry experience and market trends

One of the simplest scenarios is the laboratory department of a hospital. Many nurses are meeting the needs of a large number of patients for routine blood examinations, from blood collection, bottling, capping, centrifugation, extraction, sub-packaging to inspection. In the factory's laboratory, experts with Dr. Per capita also spend a lot of time in manual assembly line operations every day. The automation needs in these scenarios have not been met, and the field of life sciences in which they are located will be the third largest application scenario for automation in the future.

"In the field of traditional industrial robots, there are ABB, FANUC, Yaskawa, and KUKA 'Four Families', but in the 3C manufacturing field of rising stars, the market share of these 'Four Families' is very small, replaced by Yamaha, Epson, etc. Enterprises, mainly because of the different scenarios and needs of industry and 3C, for example, mobile phone assembly lines have higher rhythm requirements, which cannot be met by equipment specializing in automobile assembly lines, which makes it impossible for the 'four major families' to directly copy existing products."

After sorting out the two mature automation fields, the new automation scene will definitely give new brands the opportunity to grow into giants, and the next super industry alongside industry and 3C may be the field of life sciences .

Compared with industrial robots and 3C manufacturing robots with mature application scenarios, automation in the field of life sciences is still at the stage of 0 to 1. Based on the working background of the Robot 365 team, the Robot 365 team grasps both hands, while making technical reserves and exploring automation module products for automation in the field of robotics, while seeking industry-university-research cooperation, and in-depth cooperation with experts and scholars in the field of life sciences to achieve cross-border integration and development.

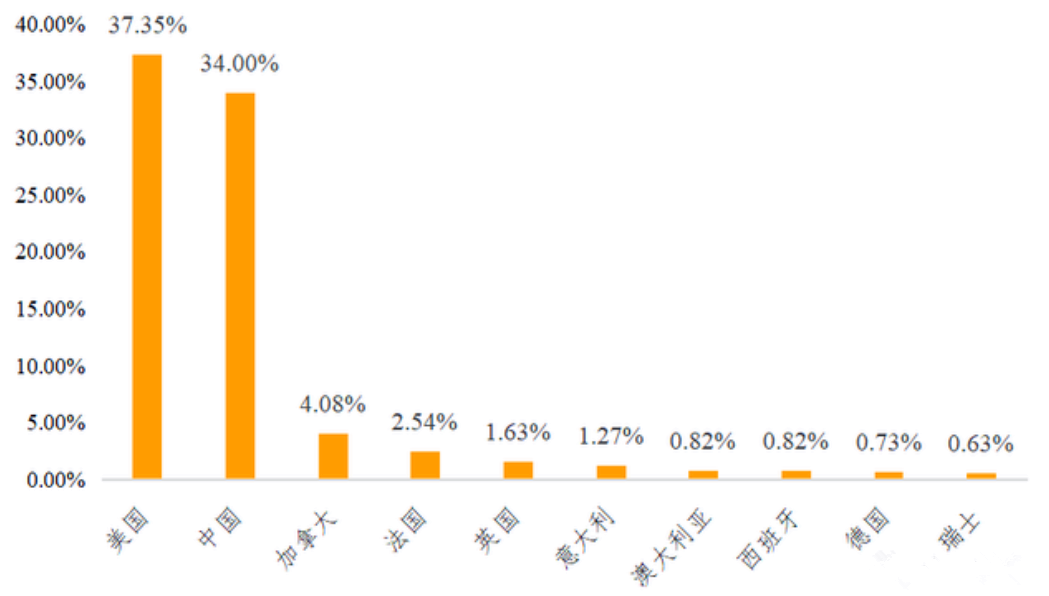

Cell culture automation brings new developments

The cell therapy products market is one of the fastest growing sub-segments of the biopharmaceutical market. In the field of stem cells, the global stem cell therapy market size in 2014 was approximately US$50.7 billion, and the global stem cell therapy market size will reach US$187 billion in 2021, with a compound annual growth rate of 22%. It is expected that the growth rate of the stem cell therapy market will continue to maintain above 20% in the future. In the field of immune cells, according to Coherent Market Insights, during 2018-2028, the global CAR-T cell therapy market value will grow at an average compound annual growth rate of up to 46.1%. In the future, North America will still occupy more than 50% of the global market share of CAR-T cell therapy, and the European market will take second place. However, with the advancement of China's CAR-T-related policies and the enhancement of research and development efforts, more and more companies are pouring into the CAR-T industry market. China is expected to overtake in a short time in the future, occupying a large part of the global market share.

With the rapid development of the cell industry, the change in automation needs is imminent. Robot 365 has taken over the needs of customers and won the battle of cell automation product delivery with high efficiency and high quality . On the second day after the order was finalized, the entire staff invested in the cell automation project. From the production and delivery of product samples to the present, the product is updated and iterated to the fully automatic intelligent cell culture system, without manual intervention in the whole process.

Cell culture preparation process

From project establishment, design drawings, synchronous software writing, sending to suppliers for processing, tracking materials, on-site assembly, debugging, and shipping, in a compact preparation cycle, Robot 365 completed high-quality product delivery in a time that far exceeded customers' expectations. . At that time, due to the impact of the epidemic, the production capacity of the supply chain was compressed and the supply of materials was tight. Colleagues of the project team all stayed on the supplier and customer side, monitoring the progress of materials 7×24 hours. In addition to the pressure of the objective environment, the complexity of the system itself is also a challenge. Taking the opening of the box and the lid as an example, it is a simple opening action done by humans , but there are a lot of technical details that need to be overcome in order to achieve automation.

Fully automatic cell culture system

" We will consider the product design thoroughly , including real-time force distance detection, deep learning , and training models for flexible fuzzy control . There are many technical patents in one link. " The previous technical reserves played a role at this time, allowing Robot 365 can be held in hand when the opportunity arises. At present, the life science automation equipment of Robot 365 has two types: lighthouse workstation and jellyfish distribution robot , which respectively replace the arm and foot movements of the experimenter. In addition, with the artificial intelligence data management system, the robot 365 technical team hopes to realize unmanned cell preparation. The factory will realize the closed-loop scenario of the entire life science intelligent laboratory in the future.

Jellyfish Mobile Distribution System

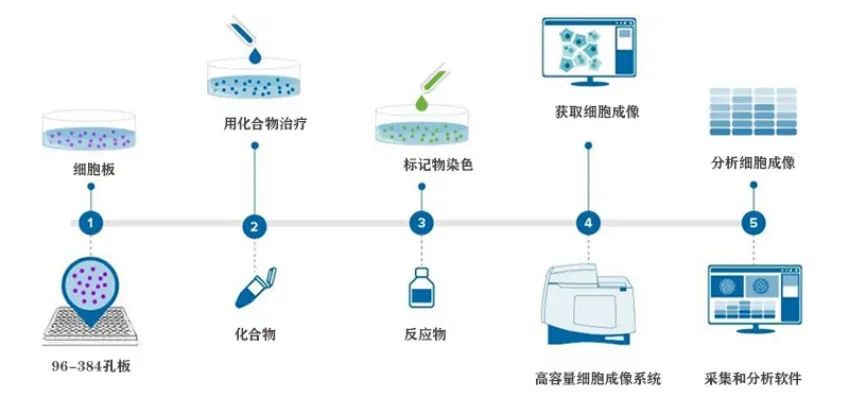

The automatic equipment in the initial stage is mainly responsible for sample distribution, and the completion of human-machine collaboration means assisting the experimenter to operate. The fully automatic laboratory system is based on the expansion of the entire link. The whole process does not require manual intervention. One-stop solution to the acquisition of experimental data results. In addition, for cell culture -related usage scenarios, Robot 365 has also launched equipment system solutions suitable for laboratory floor cleaning

Business Consulting Hotline: 0769-22288365

E-mail: robot365robot@163.com

Address:101, Building 6, Linrunzhigu, No. 1, R&D Fifth Road, Songshan Lake, Dongguan, Guangdong

Copyright © 2020-2021 Robot 365 All rights reserved Record number: 粤ICP备2021156036号 Sitemap