The right way to culture cells

2022-04-29Cell culture engineering is an important part of bioengineering. In industrial production, "cell culture" is used to process or make products. In order to realize industrial production and maximize production efficiency, it is necessary to solve the problem of whether the cell culture method is correct.

Because the product produced by cell culture technology is very sensitive to the manufacturing process, the cell culture process is exactly the same, and the quality of the product will vary from batch to batch. To minimize batch-to-batch inconsistency, periodic sampling or continuous measurements are required to keep these parameters within set values or ranges. In addition, the use of regular cell culture specifications can be more efficient and accurate to cultivate good cell products.

Preparatory work is extremely important to carry out cell culture, and the workload is also large, so it should be given enough attention. Negligence in a certain link in the preparatory work may lead to the failure or failure of the experiment. The preparatory work includes cleaning, drying and disinfection of utensils, preparation, distribution and sterilization of culture medium and other reagents, cleaning and disinfection of sterile rooms or ultra-clean workbenches, and inspection and debugging of incubators and other instruments.

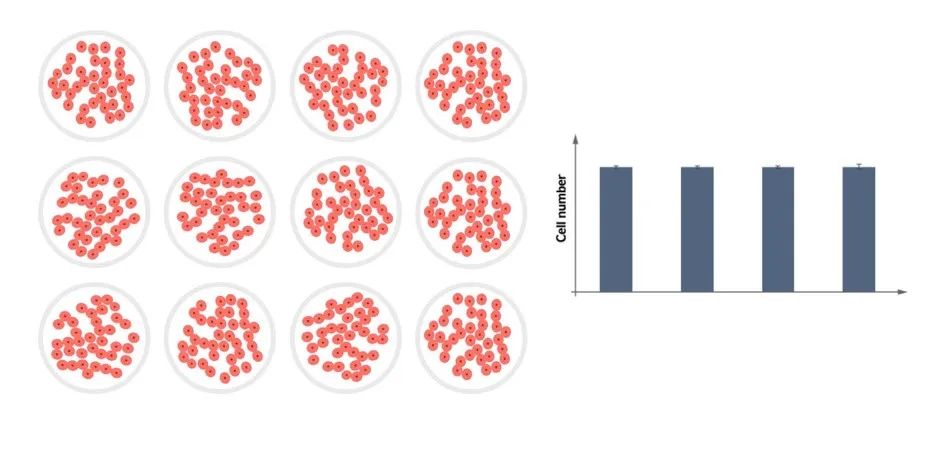

In the process of culturing cells, seeding cells is a very important starting process, because this step will directly affect your subsequent process of culturing cells. During cell transfer, pipette the cell solution to resuspend it evenly to ensure a consistent number of seeded cells, but avoid excessive pipetting to avoid shearing force.

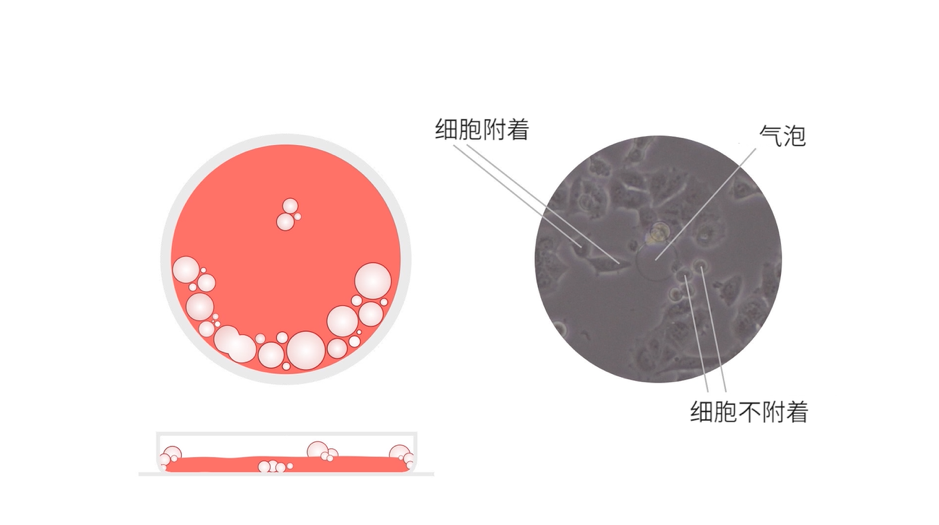

Effects of air bubbles in culture medium on cell adhesion

When culturing cells, the process of adding cell liquid to an ordinary manual pipette may cause bubbles to be generated due to the excessive operation speed. The bubbles will destroy the cell attachment, resulting in poor cell culture results and errors. Therefore, it is necessary to practice when pipetting. , to avoid the formation of air bubbles, and at the same time pay attention to eliminate air in the tip, it is best to use an external piston dispenser, because the external piston dispenser can transfer bubble-prone liquids without generating air bubbles.

The cells being cultured should be observed at regular intervals, including whether the cells grow well, whether the shape is normal, and whether there is pollution. After the cells enter the culture vessel, they should be placed in the incubator immediately, so that the cells can enter the growth state as soon as possible.

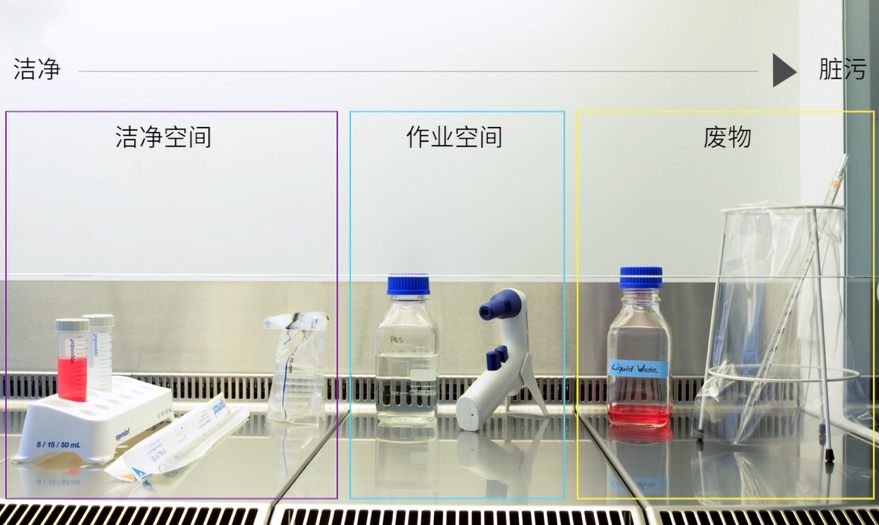

Aseptic work practices in ultra-clean benches

Cell culture is a very rigorous and professional experimental process. The principle of the ultra-clean workbench is that in a specific space, the indoor air is pre-filtered by a pre-filter, pressed into a static pressure box by a small centrifugal fan, and then passed through a high-efficiency air filter. Secondary filtration, the clean airflow blown from the air outlet surface of the high-efficiency air filter has a certain and uniform cross-sectional wind speed, which can remove the original air in the working area and take away dust particles and biological particles to form a sterile high-clean air. working environment. Therefore, experiments are generally carried out on an ultra-clean sterile workbench, so the ultra-clean workbench must be kept clean and hygienic. The ultra-clean workbench should be placed from left to right, from the clean experimental space to the dirty space where experimental waste is placed.

If too much experimental equipment is placed at will during the experiment, it is easy to block the air passage of the ultra-clean workbench, resulting in turbulent flow, and it is easy for pollutants to enter the container and contaminate the cells.

Proper management of CO₂ incubators

The CO₂ incubator is an experimental device for storing cells and culturing cells. During the experiment, it is inevitable for the experimenter to place the cell culture dish into the CO₂ incubator. At this time, we need to pay attention. The experimenter should avoid frequent switching of the CO₂ incubator. The experimental environment in the box is affected and cannot be restored in time, resulting in disturbed cell culture growth. At the same time, the samples placed in the CO₂ incubator need to be properly placed and marked correctly, so that the door of the incubator can be opened and closed quickly. General laboratory incubators are often used by many people. The incubator is equipped with inner and outer doors to minimize the impact of opening and closing the door on the environment of the incubator, avoiding the risk of experimental sample confusion and cross-contamination.

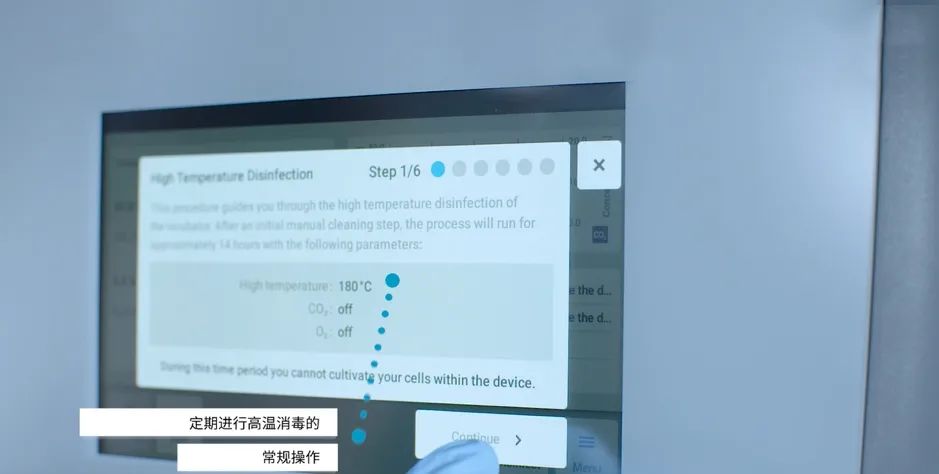

Routine maintenance and disinfection of CO₂ incubators

The CO₂ incubator needs to maintain a humid environment, so it is necessary to periodically (1-2 weeks) remove the entire liquid tray, empty the residual water, wipe and disinfect with 70% alcohol or isopropyl alcohol solution, and add sterile after drying. Distilled water and put it back into the incubator.

The CO₂ incubator generally needs to be disinfected and cleaned once a month. The experimenter needs to remove the shelves, shelves and water trays of the incubator according to the specifications, spray alcohol on the cloth, and then clean the cavity. Try to avoid the incubator. If there is a dead angle, wipe every position in the cavity, and then wipe the removed accessories and install them in place.

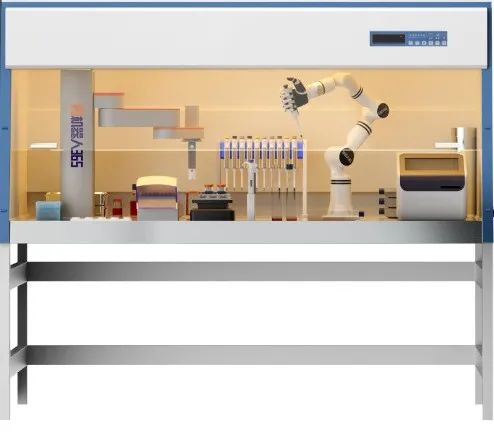

At present, automated equipment has replaced complex manual operations, and pollution can be effectively avoided by running high-temperature disinfection procedures.

Cell culture has played a key role in the development of the entire biotechnology industry. The cell culture process must be accurate, rigorous and standardized.